Machine Tools – CNC Machines

Hurco was behind in High speed machining as a result its stock was close to a dollar in late nineties. Hurco lost its market share and wanted to regain its position in the market by developing a machine 25% better than competition at a cost 25% lower than competition .

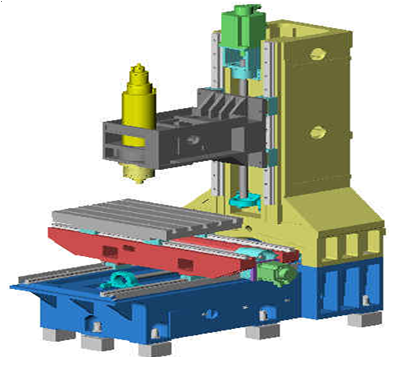

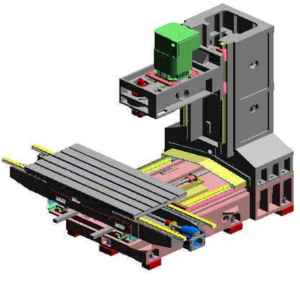

Designed a High Speed machining Center from scratch for Hurco. It took 40 people 2 years to develop 2 prototypes . The machine had approximately 800 parts. 50% of cost in a machining center is in the servo motors that drive slides. This was the first machine in the industry to use slides made by using a mold in which small granite stones and resin was used . The granite significantly lighter than steel and the resin provided surface smoothness as well as superior damping characteristics.

This resulted in faster acceleration at a lower cost and less vibrations due to damping characteristic of granite/resin composite compared to steel. The acceleration in this machine was 1 G compared to 0.1G in other Hurco machines. It had a 20,000 RPM spindle compared to other machines which had 6000 RPM spindle. The technology developed in this machine was a quantum leap for Hurco and it turned around the company and it started trading in $30 range. Before the launch it was trading in the $1 range.

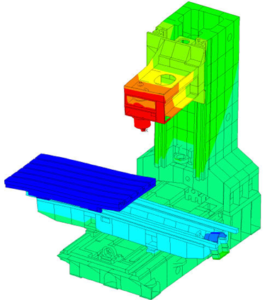

Performed simulation on all Hurco models to improve stiffness by 25% and reduce material by 10%