Metal Cutting

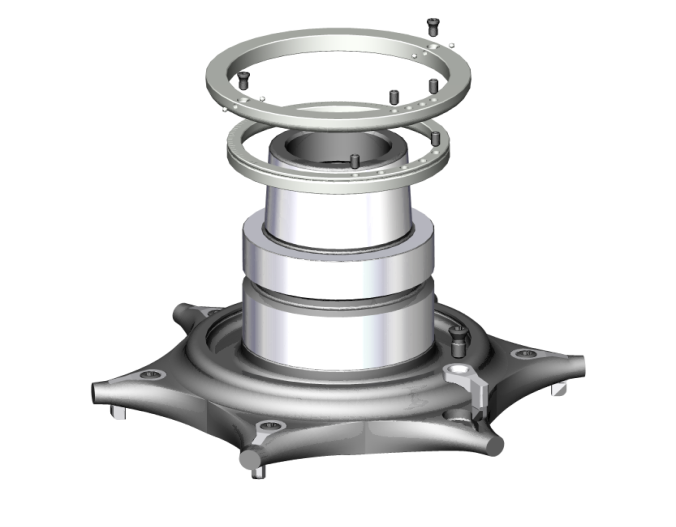

A 6 inch and 12 inch diameter supersonic cutter was designed for Kennametal . The 12 inch diameter cutter was able to achieve mach 3 peripheral speed which was 10 time faster than conventional cutter. At 10 times angular speed the stresses are 100 times because centrifugal forces is a quadratic function of angular speed.

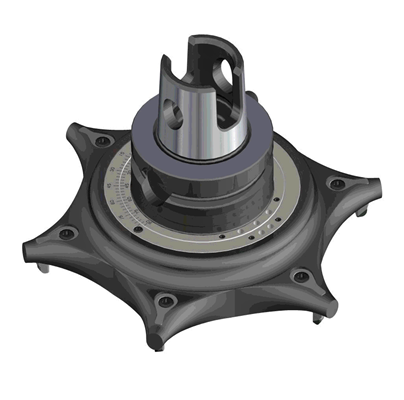

The unique star shape design maintains constant stress as you move in from the periphery to the center. I was inspired by blackbird aircraft which could reach mach 3. In order to reach mach 3 it has gaps in the fuel tank which sealed at higher speeds due to centrifugal forces. The insert in the cutter body has too much clearance but the clearance would goes away as the speed of the cutter body increases. This cutter body was invented in 1999 but it still holds the world record for the fastest cutter on the planet.

A simulation showing the model where simulation predicted failure at 55,000 RPM for a 12-inch diameter cutter . In actual spin to destruction testing the cutter body failed at 60,000 RPM and it can be seen that failure location matches very well with simulation.

“High speed milling cutter with stress equilibrating arms” P.Gupta, patent US05934842, Aug99. Also mentioned in “Fitting the tool to the job”-Brian J. Hogan, Manufacturing Engineering, SME, July 1999.

Helped Kennametal in Licensing Tuned Tooling Systems technology to reduce chatter in boring bars and milling tools which require high length to diameter ratio. This resulted in $20 million in annual sales in late nineties.